Introduction

If you are sourcing molded components or molded products, knowing how to spot a cost effective molded item can save you money without sacrificing quality. In this guide you will learn what to watch for, which factors matter, and how to choose molded products that deliver real value. You will read clear advice and practical examples so you can make informed decisions on your next order.

When a manufacturer offers molded parts at a low price, you might be tempted to buy immediately. Yet low cost does not always mean “cost effective.” A truly cost effective molded product offers good performance, durability, and reliability at a reasonable price. In other words, it balances cost and quality. Learning to identify such pieces helps you avoid hidden costs like frequent replacements, warranty issues, or poor performance. In this article, we explore key indicators of cost effective molded goods and show you how to assess them before purchasing.

What “Cost Effective Molded” Means

“Cost effective molded” describes molded parts or products that meet quality expectations while keeping costs under control. A cost effective molded item strikes the right balance between material quality, manufacturing processes, and design efficiency. It is not the cheapest molded product, but rather the best value per dollar spent. Such items save you resources in the long run, by lasting longer or performing better than cheaper alternatives that fail quickly. The goal is not just saving upfront cost — but maximizing value over the product’s full life.

Key Attributes of Cost Effective Molded Products

Material Quality and Grade

The foundation of a cost effective molded product lies in the materials used. Cheaper plastics or low‑grade resins may reduce price, but they also weaken structural integrity. A good molded piece uses materials appropriate for its function. For example, if a molded part must endure heat or load, choosing a high‑grade polymer or reinforced resin can greatly extend life. Always ask what material grade is used. If the supplier cannot specify grade or composition clearly, that is a red flag. With proper material grade, your molded item is more likely to resist wear, deformation, or environmental impact.

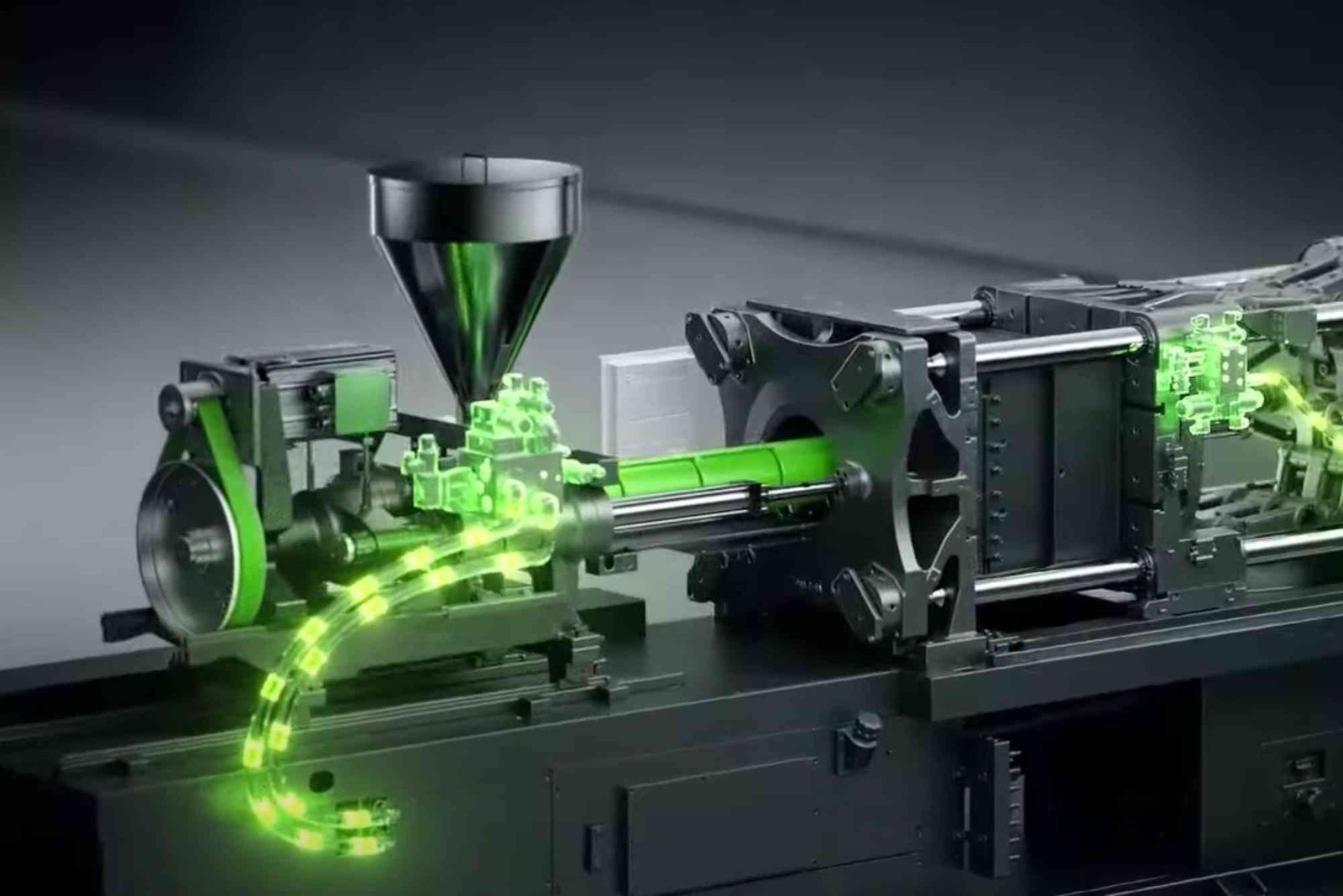

Precision of Mold Design and Manufacturing

Even with good materials, poor mold design or sloppy manufacturing ruins value. Accurate mold design ensures consistent thickness, clean edges, and uniformity across units. Well‑made molds reduce strains, stress points, and defects. If you inspect prototypes or sample parts and notice warping, uneven walls, or blemishes — those defects often stem from mold flaws. A molded item that shows tight tolerances, smooth surfaces, and symmetry signals proper mold engineering. This matters especially if the part must fit precisely with other components. Precision manufacturing is a hallmark of truly cost effective molded goods.

Efficiency in Production and Waste Reduction

A conscientious manufacturer who aims for cost effective molded production will optimize processes to minimize waste. Efficient use of resin, minimal excess trimming, and streamlined cycle times lower cost without compromising quality. That means they likely invest in good mold maintenance, temperature control, and quality checks. When you evaluate a supplier, ask about their production efficiency. A producer who emphasizes waste control often passes savings onto you. Conversely, a low‑cost item from a sloppy workshop may actually cost more over time due to defects or replacements.

Balance Between Cost and Function

Cost effective molded items deliver value by balancing affordability with function. If a molded product is intended simply for decorative or low-stress use, then a basic plastic may suffice. For demanding uses — such as load-bearing parts or components exposed to heat, moisture, or mechanical stress — investing in sturdier material and precision mold is wise. A well-balanced molded product delivers performance appropriate for its intended use. That is more cost effective than overspending on over‑engineered parts or under‑spending on weak ones.

Practical Steps to Evaluate Molded Products

Request and Inspect Samples

Before committing to a bulk order, always ask for sample molded products. Touch them, inspect visually for defects, measure critical dimensions, test for fit if they join other parts. A sample reveals imperfections in mold design, material inconsistencies, or visible defects. If possible, test the sample under real-world conditions — like heat, weight, or humidity. Observing performance under stress gives a clearer picture than specifications alone. This hands‑on evaluation helps you determine whether it truly qualifies as cost effective molded.

Ask for Material and Process Documentation

Don’t rely solely on price or appearances. Ask your supplier directly for material grade data, resin certifications, or manufacturing standards. Reliable producers often provide documentation of resin type, material safety, durability tests, or mold maintenance logs. Transparent documentation indicates professionalism and quality control. If a supplier hesitates or fails to provide these details, treat that as a warning. Proper records help ensure you get molded goods that meet expected standards — key to achieving cost effective molded results.

Evaluate Long-Term Performance, Not Just Price

A low upfront price may look attractive, but only long‑term performance reveals true value. If a molded component deforms, cracks, or wears out quickly, you end up replacing parts frequently — raising total cost of ownership. Instead, choose products that remain stable and functional over time. Reliable molded parts reduce maintenance, cut downtime, and avoid warranty disputes. That long-term reliability is central to cost effectiveness. Always think beyond initial cost and consider lifecycle value when assessing molded products.

Consider Supplier Reputation and Reviews

A supplier’s history often predicts quality and consistency. If previous clients report satisfaction with molded goods’ durability and performance, that suggests good processes and standards. On the other hand, frequent complaints about breakage, defects, or material failures may hint at cost‑cutting shortcuts. Reach out to peers, check reviews, and ask about real‑world experiences. A reputable supplier committed to quality is more likely to deliver true cost effective molded items.

Calculate Total Cost of Ownership

When evaluating any molded product, calculate not just the purchase price, but the total cost over product life. Include maintenance, replacements, downtime, or repair costs. In many cases a slightly more expensive molded product ends up cheaper because it lasts longer. Considering total cost helps you appreciate the real value of cost effective molded items. This holistic view prevents being lured by cheap but low‑quality molded pieces.

Why Some Molded Products Are Cheap — And When That’s a Warning

Naturally, some molded products are cheap for valid reasons. If the part is low‑stress, decorative, or for single‑use applications, manufacturers can afford basic materials and simple molds. That may be fine, provided you know the intended use. However, cheap molded items become a warning when used in demanding contexts — like structural parts, load-bearing frames, or long-term exposure. In such cases, lower cost often means lower quality. If a product is extremely cheap yet claims high durability, treat that as a red flag. Always match molded parts quality to their intended use.

Case Example: Choosing Molded Components for a Consumer Device

Imagine you source plastic housings for an electronic device. A supplier offers two options: one very cheap with vague material description, and another slightly pricier but with resin grade data and sample prototypes. The cheaper housing cracks easily under stress, while the pricier one stays intact after multiple thermal cycles. Which one is truly cost effective molded? Clearly, the more expensive housing saves costs over time by reducing warranty claims and replacements. This example underscores why upfront price should not be the only consideration. Evaluating material quality, mold precision, and long‑term reliability leads you to cost effective molded success.

How to Identify — Key Questions to Ask Suppliers

Before placing an order, consider asking suppliers these questions:

What material grade and resin type are used in the molding?

Can you show sample parts produced under actual production conditions?

Do you maintain mold design and maintenance records?

What tolerance and precision can you guarantee for critical dimensions?

How many cycles have sample parts undergone under stress or load?

What is the expected lifespan under typical use conditions?

Suppliers who answer clearly and provide documentation demonstrate transparency and likely follow good manufacturing practices. That boosts confidence that their molded goods are genuinely cost effective.

Common Mistakes That Undermine Cost Effectiveness in Molded Goods

A common mistake is assuming low price equals good value. Another is ignoring long‑term performance and total cost of ownership. Some buyers accept vague material claims without verification. Others overlook mold quality or inspection of samples. Even trusting supplier reputation without verification can backfire if quality control slips. Such mistakes often lead to costly replacements or failures later. Avoiding them requires awareness and diligence — exactly what this guide aims to build.

Expert Advice for Buyers and Engineers

As someone dealing with molded goods regularly, I advise you always treat molded parts procurement as a quality exercise — not a cost race. Prioritize suppliers who value documentation, consistent processes, and material traceability. Never base decisions solely on price. Look for signs of mold maintenance, process control, and sample testing. In many cases, spending a bit more on material or mold quality delivers far greater savings later. That mindset makes the difference between cheap molded and truly cost effective molded. If possible, build a checklist of quality criteria and ensure suppliers meet those standards before placing orders.

Make Smart Decisions for Durable Molded Goods

In summary, identifying cost effective molded products requires careful evaluation of material quality, mold precision, manufacturing efficiency, and long‑term performance. Always inspect samples, request documentation, and calculate total cost of ownership. Avoid relying on price alone. By following these steps, you can choose molded goods that deliver real value and avoid the hidden costs of poor quality. If you want to dive deeper into procurement strategies or evaluate a potential supplier, start with the guide on How To Identify and How To Identify Cost molded products for greater savings. For general background and molding info, Read more on en.wikipedia.org. If you’re ready to source smarter molded goods, contact a trusted supplier today to request samples, documentation, and long‑term quality assurance. Make cost effective molded selection your standard.

FAQs

How can I tell if a molded pr3oduct is truly cost‑effective?

You need to look beyond price. Request sample parts and inspect them for quality, material grade, and mold precision. Test their durability under expected use conditions before sourcing in bulk.

Does a higher price always mean better molded parts?

Not always — but often a moderately higher cost reflects better material, molds, and quality control. Such parts tend to last longer and add value over time. Avoid very cheap parts claiming high durability without evidence.

Are molded products with no clear material documentation risky?

Yes. Without clear resin grade data or certifications, you risk hidden flaws. Always request material specs and process documentation before buying.

Can a defective mold design ruin even good materials?

Absolutely. Poor mold design can cause weak spots, inconsistent thickness, or defects. Even high‑grade material fails if mold is poorly engineered or maintained.

Is low-cost molding always a bad idea?

No — for simple, low‑stress, or disposable parts, low-cost molding may be acceptable. Just ensure you match material and process to the intended use.